Manufacturer for Laser Welding Aluminum - Laser Paint Stripping Machine for Industrial – HRC

Manufacturer for Laser Welding Aluminum - Laser Paint Stripping Machine for Industrial – HRC Detail:

Description

Machine Introduction

Using the latest generation fiber laser source and Independently developed, HRC Laser hand-held laser welding machine Filled in the blank of hand-held welding in laser equipment industry.

Technical Parameter

| Model | FTW-SL-1000 | FTW-SL-1500 | FTW-SL-2000 |

| Laser Power | 1000W | 1500W | 2000W |

| Laser Source | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE |

| Laser Head | OSPRI | OSPRI | OSPRI |

| Fiber Wire Length | 5/10 Meters | 5/10 Meters | 5/10 Meters |

| Laser Wavelength | 1070nm | 1070nm | 1070nm |

| Operate Mode | Continuation/Modulate | Continuation/Modulate | Continuation/Modulate |

| Water Chiller | Hanli/S&A | Hanli/S&A | Hanli/S&A |

| Spot Adjusting Range | 0.1-3mm | 0.1-3mm | 0.1-3mm |

| Repeating Precision | ±0.01mm | ±0.01mm | ±0.01mm |

| Cabinet Size | 744*941*1030mm | 744*941*1030mm | 750*1260*1110mm |

| Machine Weight | About 200KG | About 200KG | About 220KG |

| Voltage | 110V/220V/380V | 110V/220V/380V | 110V/220V/380V |

Machine Tips

1. About Fiber Cable Length

Usually standard length is 10m, if you have other needs, we support shortening or lengthening.

2. Auxiliary gas: nitrogen or argon

If the welding surface effect is required to be white and bright, nitrogen or argon is required.

If there is no requirement for the welding surface, add compressed air freeze Dryer, air is ok.

3. About wire feeder

It’s the machine standard configuration, we will send to you together with the whole machine.

4. Machine warranty

usually 2 years, we have professional after sale group, 24 hour online.

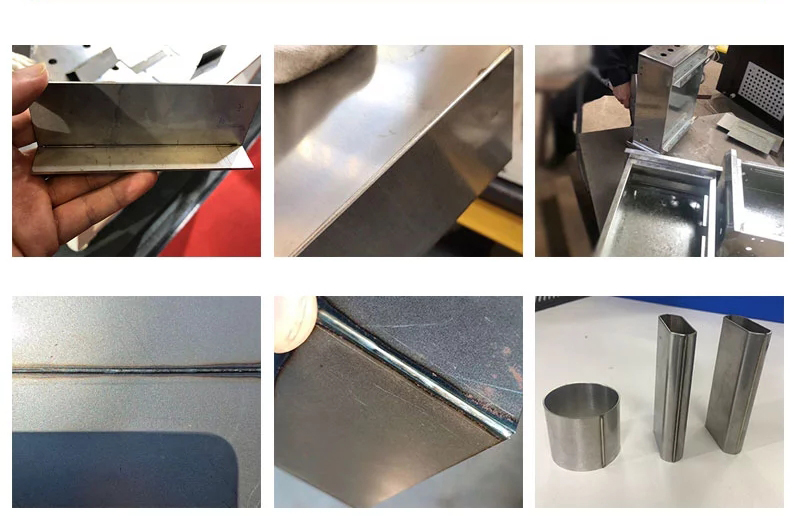

Machine Application

HRC laser welding machine Application in Stainless steel, Carbon steel, Aluminum, Copper materials, etc.

Beautiful weld, fast speed, no consumables, no welding mark, no discoloration, no need to polish later. Can be configured with a variety of Angle nozzle to meet the welding needs of different products.

OSPRI (QILIN) Fiber Laser Welding Head

1. Swing welding head

The process that traditional magnetic head cannot complete, the swing welding head only needs to use 70% of the power, which can save the cost of the laser; In addition, the swing welding method is adopted, the width of the welding joint is adjustable, and the welding fault tolerance is strong, which makes up for the small shortcomings of the laser welding joint. The tolerance range and welding width of the processed parts are enlarged, and a good welding forming effect is obtained.

2. 360 degree micro welding

After the laser beam is focused, the point can be accurately positioned and used for group welding of small and micro workpieces to achieve mass production.

3. Handheld laser welding head Nozzles

When we have a fiber handheld laser welder and replace the welding nozzle with a cutting nozzle, we can call it a handheld fiber laser welding and cutting machine. Isn’t it a great name! !!!

It can take the optical fiber from the fiber laser and gather it to a tiny point to produce a high intensity laser for cutting purpose. However, please note that it is not able to cut too thick material.

Laser Welding Head

Smart high frequency swing welding head. Can be widely used in metal equipment, stainless steel home and other industries complex irregular welding process.

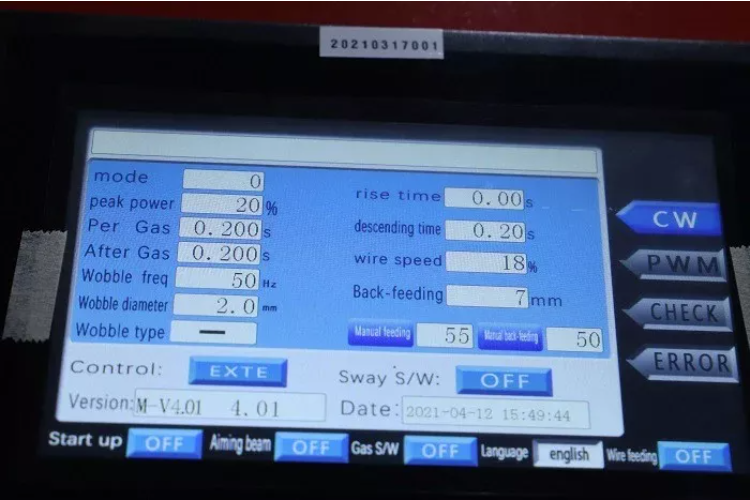

Control Panel

Control system with auto layout optimization, ensure high speed operation of whole machine.

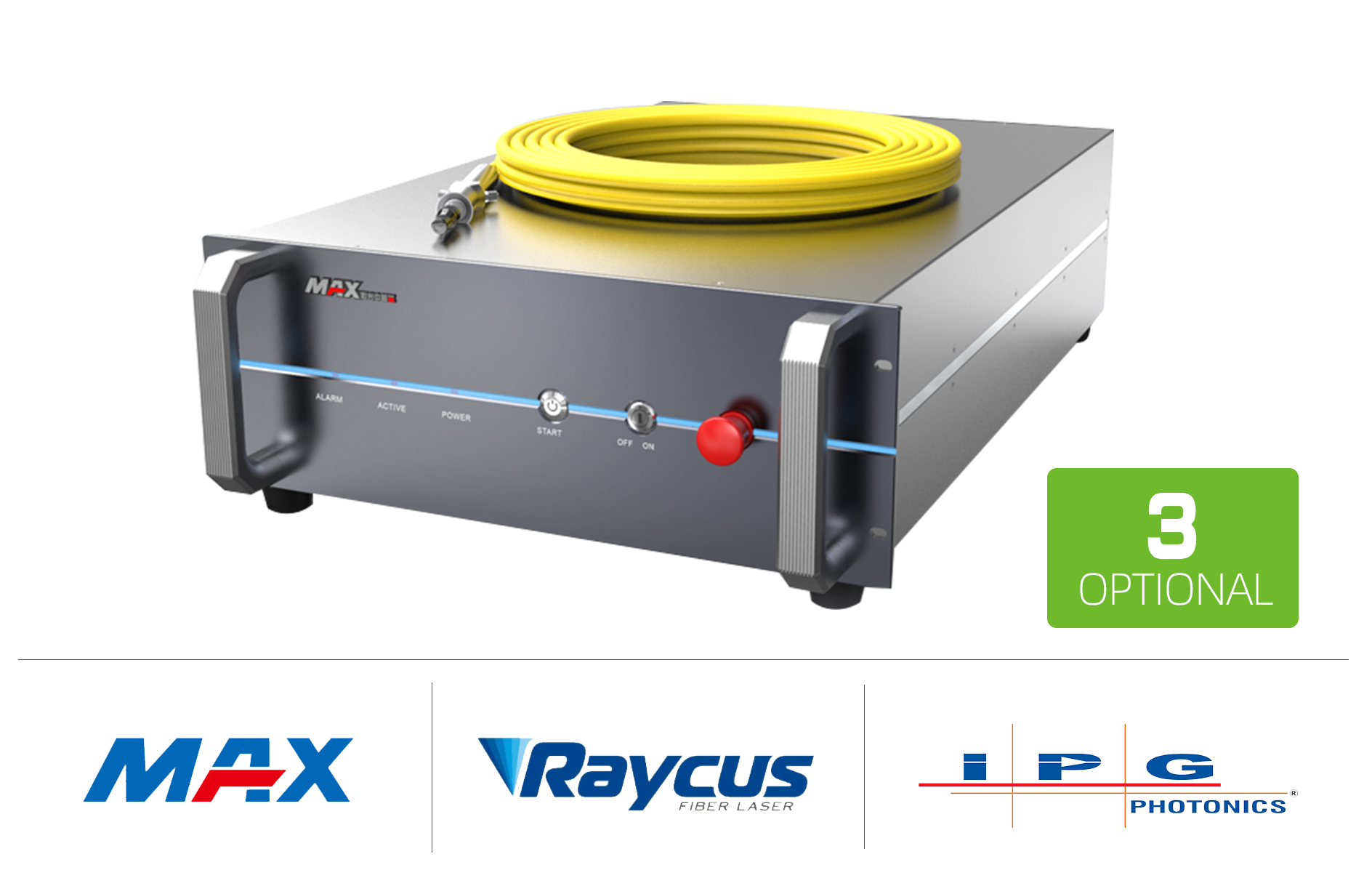

Laser Source

top brand fiber laser source Max, high power. The energy density is high, the heat input is low, the amount of thermal deformation is small.

Automatic wire feed

No consumables, small size, flexible processing, low operating and maintenance costs.

FAQ

1. After Sales

We provide 1-3 year’s guarantee and life-long maintenance for our products. Free repairing or replacement (except for wearing parts) is available for our products for their functional defects (except for artificial or force majeure factors) within warranty period. After warranty period, we only charge artifacts according to the actual situation.

2. Quality Control

Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure.

All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department.

We will provide detailed Machine pictures and Test videos to customers before delivery.

3. OEM Service

Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc.

No MOQ required.

4. Privacy

None of your personally identifiable information ( such as your name, address, emailaddress, bank info, etc ) will be disclosedor shared with any third partes.

Contact All of your inquiries or questions or helps will be answered within 24 hours, even in holiday. Also, please feel free to call us if you have any emergency questions.

5. Payment terms

Alibaba Trade Assurance ( New, safe and popular payment terms).

30% T/T paid in advance as deposit, the balance paid before shipment.

lrevocable LC at sight.

Other payment terms: Paypal, Western Union and so on.

6. Documents Support

All Documents for clearance customs support: Contract, Packing list, CommercialInvoice, Export declaration and so on.

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Manufacturer for Laser Welding Aluminum - Laser Paint Stripping Machine for Industrial – HRC , The product will supply to all over the world, such as: Liberia, Cairo, Bulgaria, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products we offer, effective and satisfying consultation service is supplied by our specialist after-sale service group. Solution lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we are going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

Managers are visionary, they have the idea of mutual benefits, continuous improvement and innovation, we have a pleasant conversation and Cooperation.