Laser Welding Machine for Aluminum

Product Introduction

Introduction

With the continuous progress of technology, handheld laser welding machines have gradually been applied in various fields, including agricultural machinery. This new welding method has brought revolutionary changes to the manufacturing and maintenance of agricultural machinery due to its high efficiency, precision, and easy operation. This article will provide a detailed introduction to the principles, advantages, and applications of handheld laser welding machines in agricultural machinery.

Overview of Handheld Laser Welding Machine

A handheld laser welding machine is an efficient and accurate welding equipment that uses laser as a heat source and transmits through optical fibers to achieve long-distance and high-precision welding operations. Compared with traditional arc welding, laser welding has higher energy density, faster cooling speed, and deeper penetration, which can achieve efficient and high-quality welding.

Product Introduction

MACHINE DETAILS

High performance brand fiber laser

Longer life, higher electro-optical conversion rate, 24 hours continuous work, long dimensional-free cycle, reduce maintenance costs

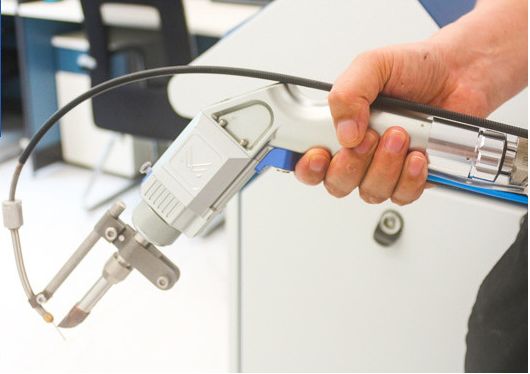

High quality handheld laser welding head

Lightweight and flexible, long-term work without fatigue, matching welding copper nozzle and infrared positioning, to achieve any part, Angle welding.

Lengthened welded connection optical fiber

Equipped with 5~10 meters brand optical fiber can achieve ultra-long distance operation can reach a wide distance, flexible and convenient.

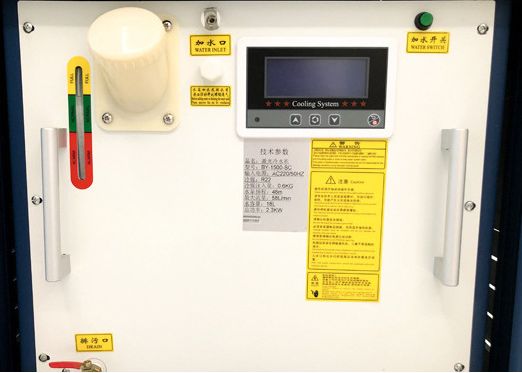

LCD panel control system

Simple and clear, preset a variety of process modes, without complex training, easy to master, preset multiple security alarms, more reliable.

Manual button control switch

One-key boot, simple and easy to use, multi-parameter adjustment range, long life, more practical.

Built-in intelligent double temperature laser chiller

Intelligent temperature control, dust and condensation prevention, rapid cooling, no trace of hot air, stable performance, energy saving, improve the service life of the equipment.

Automatic wire feeder

Fast wire feeding, wire feeding specifications include 0.8/1.0/1.2/1.6 four specifications, wire feeding speed is adjustable, equipped with manual wire feeding/withdrawal function.

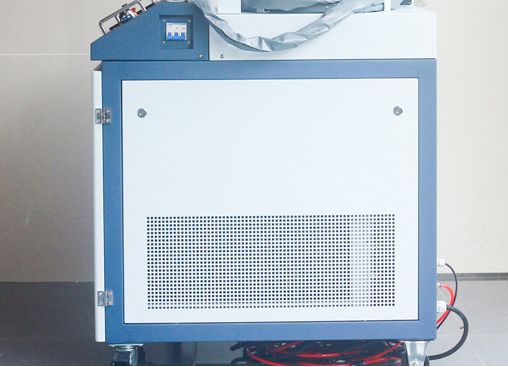

Sheet metal cabinet

Protection is convenient for single work

The industry meets the size ratio of industrial needs.

The advantages of handheld laser welding machines

Efficiency: The efficiency of laser welding is much higher than that of traditional arc welding, which can greatly shorten welding time and reduce labor costs.

Precision: Laser welding can achieve precise fixed-point welding, making it more convenient for welding complex shapes and structures.

Easy to operate: The handheld laser welding machine is easy to operate and can be operated by workers who have received simple training.

Flexibility: The handheld design allows the laser welding machine to operate flexibly even in space limited environments.

Environmental friendliness: The laser welding process is smokeless, odorless, and noise free, with minimal impact on the environment.

The application of handheld laser welding machine in agricultural machinery

Agricultural machinery maintenance: Agricultural machinery is prone to various malfunctions and damages during long-term use. Handheld laser welding machines can quickly and accurately repair damaged components, improve the repair efficiency of agricultural tools, and extend their service life.

Agricultural machinery manufacturing: In the manufacturing process of agricultural machinery, high-precision welding technology is required. Handheld laser welding machines can achieve high-quality welding, improve the quality and stability of agricultural machinery. For example, when manufacturing large agricultural machinery such as tractors and harvesters, handheld laser welding machines can improve production efficiency and reduce costs.

Greenhouse manufacturing: Greenhouses are commonly used facilities in modern agricultural production, and their welding quality directly affects the stability and service life of greenhouses. The handheld laser welding machine can achieve high-quality docking and overlapping, improving the manufacturing efficiency and safety of greenhouse.

Manufacturing of feed processing equipment: Feed processing equipment requires high-precision welding technology. Handheld laser welding machines can achieve high-quality docking and overlapping, improving the quality and stability of feed processing equipment.

Manufacturing of breeding equipment: Breeding equipment requires high-precision welding technology. Handheld laser welding machines can achieve high-quality docking and overlapping, improving the quality and stability of breeding equipment. For example, the precision and efficiency of handheld laser welding machines can improve production efficiency and quality when manufacturing breeding equipment such as chicken cages and pigstys.

TECHNICAL PARAMETER

| Machine Type: | Laser welding machine | Product name: | Handheld fiber laser welding machine |

| Laser power: | 2000W | Laser wavelength: | 1080nm±5 |

| Modulation frequency: | 5000Hz | fiber length: | 15m |

| The way the light swings: | Straight line/point | Swings the frequency: | 0-46Hz |

| Maximum welding speed: | 10m/min | Cooling method: | Built-in water cooler |

| Input voltage : | 220V/380V 50Hz±10% | Current: | 35A |

| Machine power: | 6KW | Operating environment temperature: | Temperature :10℃~35℃ |

Conclusion

The emergence of handheld laser welding machines has brought new opportunities and challenges to the field of agricultural machinery. It has become a new and efficient welding method in agricultural machinery manufacturing and maintenance due to its high efficiency, precision, and ease of operation. With the continuous progress of technology and the expansion of application fields, the application of handheld laser welding machines in the field of agricultural machinery will be more extensive, bringing more possibilities for the development of agricultural production.

Packing & Shipping

The machine would be packed in solid wooden crate for international shipping, suitable for sea, air and express transportation.