Handheld Laser Welding Machine for Mold Repair

Product Introduction

Introduction

With the continuous development of technology, the application of handheld laser welding machines in the construction industry has become a trend. This new welding method has brought revolutionary changes to the construction industry due to its high efficiency, precision, and easy operation. This article will provide a detailed introduction to the principles, advantages, and applications of handheld laser welding machines in the construction industry.

Overview of Handheld Laser Welding Machine

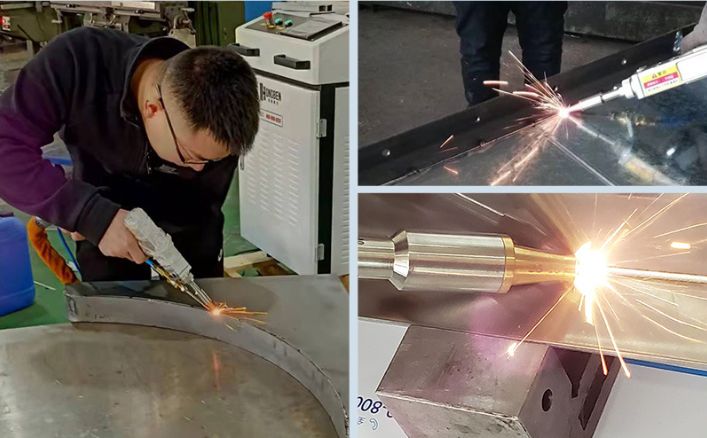

A handheld laser welding machine is an efficient and accurate welding equipment that uses laser as a heat source and transmits through optical fibers to achieve long-distance and high-precision welding operations. Compared with traditional arc welding, laser welding has higher energy density, faster cooling speed, and deeper penetration, which can achieve efficient and high-quality welding.

Machine Details

The advantages of handheld laser welding machines

Efficiency: The efficiency of laser welding is much higher than that of traditional arc welding, which can greatly shorten welding time and reduce labor costs.

Precision: Laser welding can achieve precise fixed-point welding, making it more convenient for welding complex shapes and structures.

Easy to operate: The handheld laser welding machine is easy to operate and can be operated by workers who have received simple training.

Flexibility: The handheld design allows the laser welding machine to operate flexibly even in space limited environments.

Environmental friendliness: The laser welding process is smokeless, odorless, and noise free, with minimal impact on the environment.

The application of handheld laser welding machines in the construction industry

Welding of steel bars: In the construction industry, the welding of steel bars is a very important process. The handheld laser welding machine can quickly and accurately complete the docking and overlapping of steel bars, improving construction efficiency.

Steel structure welding: Steel structure is a commonly used structural form in modern architecture, and its welding quality directly affects the safety of the building. Handheld laser welding machines can achieve high-quality welding, improve the quality and stability of steel structures.

Glass curtain wall welding: The installation of glass curtain walls requires high-precision welding technology. The handheld laser welding machine can achieve high-quality docking and overlapping, improving the installation efficiency and safety of glass curtain walls.

Pipeline welding: In the construction industry, pipeline welding is also a very important link. Handheld laser welding machines can achieve high-quality docking and overlapping, improving the safety and stability of pipelines.

Decoration welding: A large amount of welding work is required in decoration, and the flexibility and accuracy of handheld laser welding machines make decoration work more efficient and beautiful.

Conclusion

The emergence of handheld laser welding machines has brought new opportunities and challenges to the construction industry. It has become a new and efficient welding method in the construction industry due to its high efficiency, precision, and ease of operation. With the continuous progress of technology and the expansion of application fields, the application of handheld laser welding machines in the construction industry will be more extensive, bringing more possibilities for the development of the construction industry.

The speed is 3~10 times faster than traditional welding

Handheld Laser Welding Speed Can Reach 120mm/s

Machine Detail

TECHNICAL PARAMETER

| LASER POWER | 1000W | 1500W | 2000W |

| Melting depth (stainless steel, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Melting depth (carbon steel, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Melting depth (aluminum alloy, 1m/min) | 2mm | 3mm | 4mm |

| Automatic wire feeding | φ0.8-1.2 welding wire | φ0.8-1.6 welding wire | φ0.8-1.2 welding wire |

| Power consumption | ≤3kw | ≤4.5kw | ≤6kw |

| Cooling method | water cooling | water cooling | water cooling |

| Power demand | 220v | 220v or 380v | 380v |

| Argon or nitrogen protection (customer's own) | 20 L/min | 20 L/min | 20 L/min |

| Equipment size | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Equipment weight | ≈150kg | ≈170kg | ≈185kg |

Packing & Shipping

The machine would be packed in solid wooden crate for international shipping, suitable for sea, air and express transportation.