Handheld Laser Welder for Metal

TECHNICAL PARAMETER

Introduction

With the development of technology, laser welding technology, as an efficient and high-quality welding method, has been widely applied in the shipbuilding industry. Among them, handheld laser welding machines gradually occupy a dominant position in the industry due to their flexibility and efficiency. This article will provide a detailed introduction to the application of handheld laser welding machines in the shipbuilding industry.

Introduction to Handheld Laser Welding Machine

The handheld laser welding machine is a high-precision, high-power laser welding equipment with the advantages of simple operation, strong portability, fast welding speed, small heat affected zone, and high weld quality. It achieves efficient and high-quality welding by irradiating the surface of shipbuilding materials with high-energy laser beams.

Application field

Hull structure welding: Hull structure is an important part of ship manufacturing, and traditional welding methods are difficult to meet the needs of modern ship manufacturing due to issues such as low efficiency and poor weld quality. The emergence of handheld laser welding machines has greatly improved the welding efficiency and quality of ship structures due to their advantages of high accuracy and speed.

Deck and cabin welding: The deck and cabin are key parts of the ship, requiring extremely high welding quality. The handheld laser welding machine can achieve high-strength and high sealing welding, meeting the welding needs of decks and cabins.

Welding of pipelines and accessories: The welding quality of pipelines and accessories is directly related to the safety and performance of ships. The handheld laser welding machine performs excellently in the welding of pipelines and accessories, enabling precise and fast welding.

Fast speed. no blackness. no deformation

TECHNICAL PARAMETER

| Device Name | Handheld Laser Welding Machine | Laser Power | 1000w-3000w |

| Water Chiller | Hanli | Water Request in Water Chiller | Distilled Water/Pure Water |

| Protective Gas | N2/AR | Operating voltage | AC220 |

| Wire feeding | Automatic | The ambient humidity | Less than 70% without condensation |

| Laser wavelength | 1070 土10nm | Operating temperature | -10C or 45C |

| The gap request | <0.5mm | Maximum melting depth | 8mm |

| Aiming and fixing | Infrared ray | Gas consumption | 20ml/min |

| Automatic welding port supports | yes | Light spot range | 0 to 5mm |

| Fiber length | standard 10m | Pulse width | 0.3mm~10mm |

| Welding capacity | 0.5-4mm | Warranty | 1 year |

Advantages and Effects

Improving welding efficiency: Compared to traditional welding methods, handheld laser welding machines have higher welding speed and deposition efficiency, greatly shortening the shipbuilding cycle.

Improving weld quality: Due to the small heat affected zone of laser welding, the microstructure of the weld is more dense, which improves the quality of the weld. At the same time, the precise control of handheld laser welding machines also avoids the defects that may arise from traditional welding methods.

Reducing manufacturing costs: The high deposition efficiency of laser welding improves material utilization, reduces material consumption and waste generation, and reduces manufacturing costs.

Improving production safety: Traditional welding methods can generate harmful factors such as arc light and smoke during operation, posing a threat to workers' health. During the laser welding process, there is no generation of arc light, smoke, etc., which improves production safety.

Outlook

With the continuous development of technology, the performance and functionality of handheld laser welding machines will be further improved. Its application in the shipbuilding industry will also be more extensive, not only limited to the welding of hull structures, decks and cabins, pipelines and accessories, but also expanded to more fields such as ship interior decoration and component manufacturing. Meanwhile, with the promotion of green manufacturing and intelligent manufacturing, the application of handheld laser welding machines in ship manufacturing will also be more environmentally friendly, efficient, and intelligent.

Conclusion

The application of handheld laser welding machines is a major technological innovation in the shipbuilding industry, providing strong support for shipbuilding with its advantages of high efficiency and quality. With the continuous progress of technology, we have reason to believe that handheld laser welding machines will play a more important role in the future shipbuilding industry.

Storage Racks

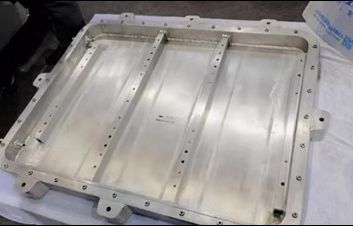

Aluminum profile shell for new energy vehicles

Kitchen and bathroom customization

Medical purified water equipment

Packing & Shipping

The machine would be packed in solid wooden crate for international shipping, suitable for sea, air and express transportation.