3000w laser welder

TECHNICAL PARAMETER

| LASER POWER | 1000W | 1500W | 2000W |

| Melting depth (stainless steel, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Melting depth (carbon steel, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Melting depth (aluminum alloy, 1m/min) | 2mm | 3mm | 4mm |

| Automatic wire feeding | φ0.8-1.2 welding wire | φ0.8-1.6 welding wire | φ0.8-1.2 welding wire |

| Power consumption | ≤3kw | ≤4.5kw | ≤6kw |

| Cooling method | water cooling | water cooling | water cooling |

| Power demand | 220v | 220v or 380v | 380v |

| Argon or nitrogen protection (customer's own) | 20 L/min | 20 L/min | 20 L/min |

| Equipment size | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Equipment weight | ≈150kg | ≈170kg | ≈185kg |

Application of handheld laser welding machine in the aerospace industry

Introduction

In the aerospace industry, high-quality welding processes are crucial for ensuring the safety and performance of aircraft. In recent years, handheld laser welding machines have gradually gained popularity in the industry due to their unique advantages. This article will provide a detailed introduction to the application of handheld laser welding machines in the aerospace industry.

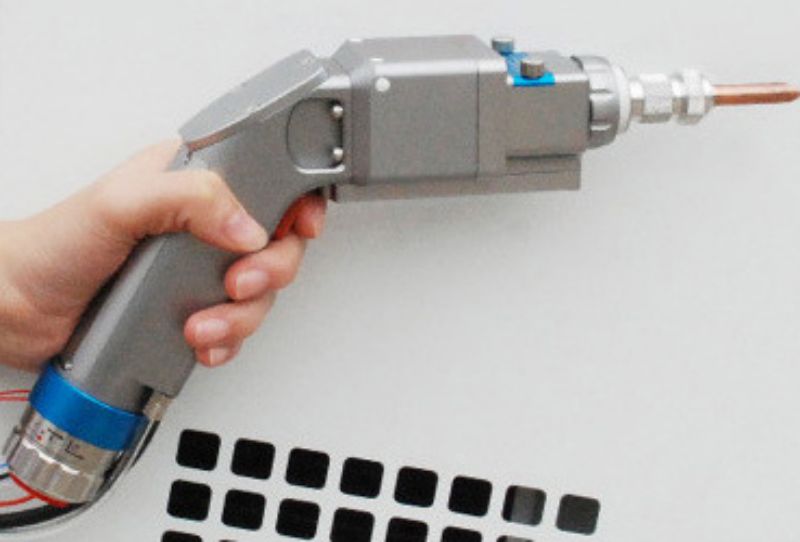

Introduction to Handheld Laser Welding Machine

The handheld laser welding machine is an advanced laser welding equipment that uses a high-energy laser source, transmitted through optical fibers, and accurately aimed and adjusted by an advanced control system. The handheld laser welding machine has the advantages of simple operation, strong adaptability, fast welding speed, and high welding quality.

Application in the aerospace industry

High quality welding: The handheld laser welding machine can achieve precise aiming and adjustment, thereby ensuring the quality and accuracy of welding. In the aerospace industry, the control of welding quality is very important, and the application of handheld laser welding machines can greatly improve welding quality.

Efficiency: The handheld laser welding machine can complete high-quality welding operations in a short period of time, greatly improving production efficiency. This is very important for the aerospace industry, as it requires the processing of a large number of parts and components, and efficient production processes are crucial for ensuring the quality and progress of aircraft manufacturing.

Flexibility: Handheld laser welding machines have high flexibility and can handle various complex welding needs. Whether it's spot welding, butt welding, or fillet welding, handheld laser welding machines can easily handle it. This flexibility gives it great advantages in handling components of various shapes and sizes.

Adaptability: The handheld laser welding machine can adapt to various materials of components, including metal, non-metal, etc. This adaptability enables it to play an important role in handling various types of aircraft.

Environmental friendliness: The handheld laser welding machine does not produce harmful substances during the welding process and meets environmental requirements. In the aerospace industry, environmental friendliness is a very important consideration, so the application of handheld laser welding machines can help reduce the impact on the environment.

Conclusion

The advantages of handheld laser welding machines make them widely applicable in the aerospace industry. It can not only improve production efficiency, but also cope with various complex welding needs. At the same time, its environmental friendliness and labor-saving characteristics also make it an ideal choice for the aerospace industry. With the continuous development of technology, the performance and functions of handheld laser welding machines will also be further improved and improved, and their applications in the aerospace industry will also be more extensive and in-depth.

Welding quality improvement Six welding modes

It can complete the welding requirements that cannot be completed by ordinary welders, and the weld is firm and beautiful ,No welding slag, not easy to deformation, black

Spot welding: small spot, strong energy, spot welding mode can be used when the material has welding penetration requirements;

Straight line: the width can be adjusted, the material has penetration, in splicing welding, wire feeding welding,Positive fillet welding can use the linear welding mode;

"O" type: adjustable diameter, uniform distribution of energy density; High frequency when welding sheet "O" welding can be used;

Double "O": adjustable diameter, reduce light spot, suitable for welding at various angles;

Triangle: The width can be adjusted to reduce the light spot while the energy of the three edges is uniform. The middle and both sides of the plate are fully heated;

"8" word: continue to increase the light spot on the basis of the triangle, so that the plate is repeatedly heated, large.

The "8" pattern can be used for width welding.

Packing & Shipping

The machine would be packed in solid wooden crate for international shipping, suitable for sea, air and express transportation.