3 In 1 Laser Cleaner Welder Cutter

Description

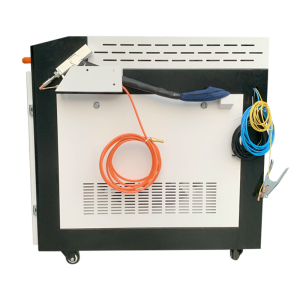

The Mini Type handheld Fiber laser welding machine combines the fundamental qualities of an ultra-portable device with uncompromising performance.

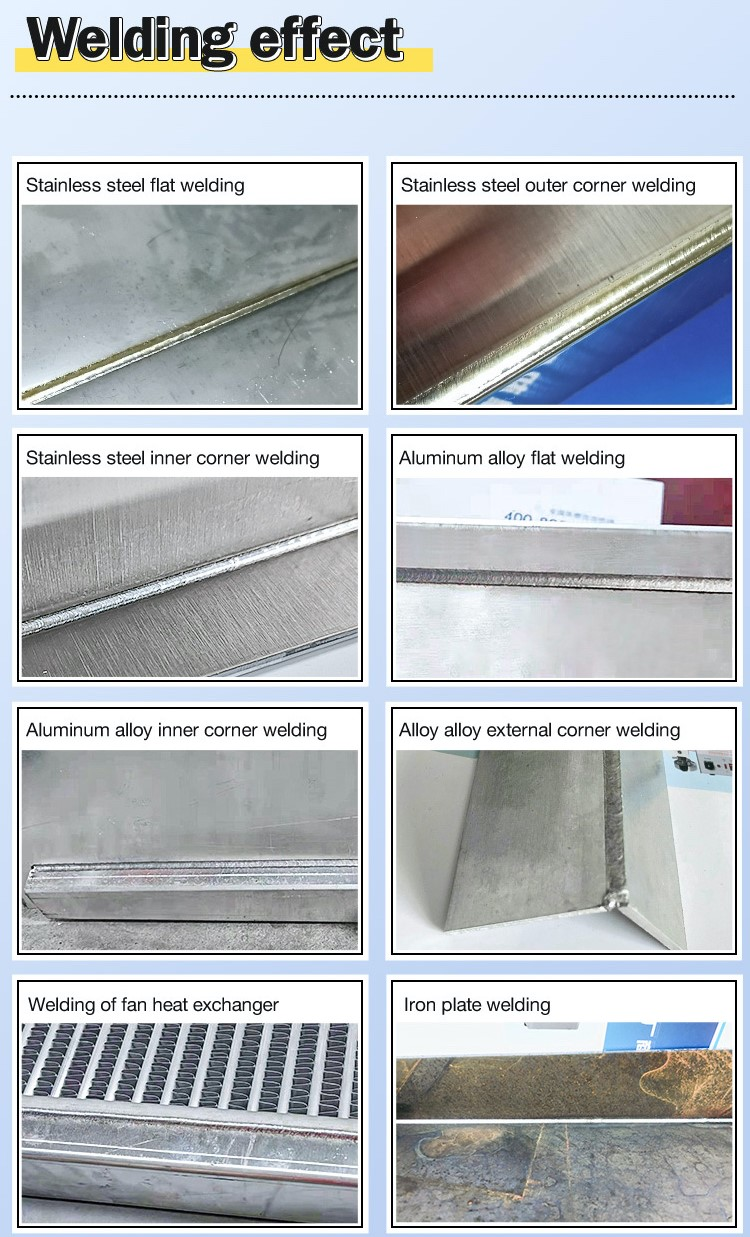

FTW-SL-1000/1500/2000 Mini handheld laser welding machine adopts the latest generation of fiber laser and is equipped with OSPRI handheld laser welding head, which fills the gap of handheld welding in the laser equipment industry. With the advantages of fast welding speed and no consumables, it can perfectly replace traditional argon Arc(TIG) welding, electric welding and other processes when welding thin stainless steel plates, iron plates, galvanized plates and other metal materials. Hand-held laser welding machine can be widely used in complex and irregular welding processes in cabinet kitchen and bathroom, stair elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries.

OEM Customized China Laser Cleaner and Laser Welder, During in 11 years,Now we have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to deliver the customer best products and solutions with lowest price. We've been making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We'll always be your first choice. Trust us, you will never lose heart.

Technical Parameter

| Model | FTW-SL-1000 | FTW-SL-1500 | FTW-SL-2000 |

| Laser Power | 1000W | 1500W | 2000W |

| Laser Source | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE | Raycus/Max/IPG/ SUNLITE |

| Laser Head | OSPRI | OSPRI | OSPRI |

| Fiber Wire Length | 5/10 Meters | 5/10 Meters | 5/10 Meters |

| Laser Wavelength | 1070nm | 1070nm | 1070nm |

| Operate Mode | Continuation/Modulate | Continuation/Modulate | Continuation/Modulate |

| Water Chiller | Hanli/S&A | Hanli/S&A | Hanli/S&A |

| Spot Adjusting Range | 0.1-3mm | 0.1-3mm | 0.1-3mm |

| Repeating Precision | ±0.01mm | ±0.01mm | ±0.01mm |

| Cabinet Size | 744*941*1030mm | 744*941*1030mm | 750*1260*1110mm |

| Machine Weight | About 200KG | About 200KG | About 220KG |

| Voltage | 110V/220V/380V | 110V/220V/380V | 110V/220V/380V |

Handheld Laser Welding and Cleaning Systems

HRC Laser Fiber Laser Welder Unbeatable Benefits

* FAST: Up to 4X faster than TIG.

* VERSATILE: Wide range of materials – up to 6.35 mm.

* EASY: Optimized presets reduce learning curve.

* CONSISTENT: High-quality, repeatable results.

* FLEXIBLE: Simple and challenging applications.

* PRODUCTIVE: Pre- and post-weld cleaning capability.

* Adjustable laser welding power up to 2000 W.

* Preset & user-defined modes optimize material-thickness combinations.

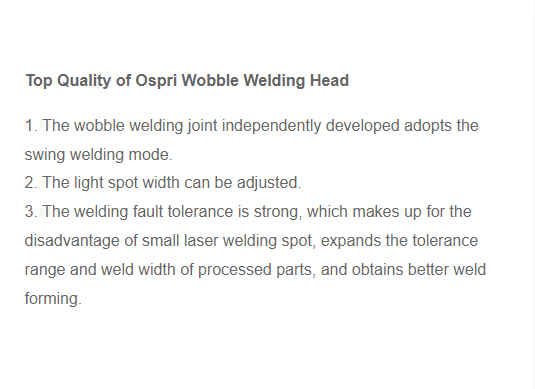

* Wobble welding controls for 5 mm of additional weld width.

* Rear panel provides intuitive connections for power, process gas and external accessory controls.

* Cleaning power up to 2000 W peak for greater welding quality and finishing capability.

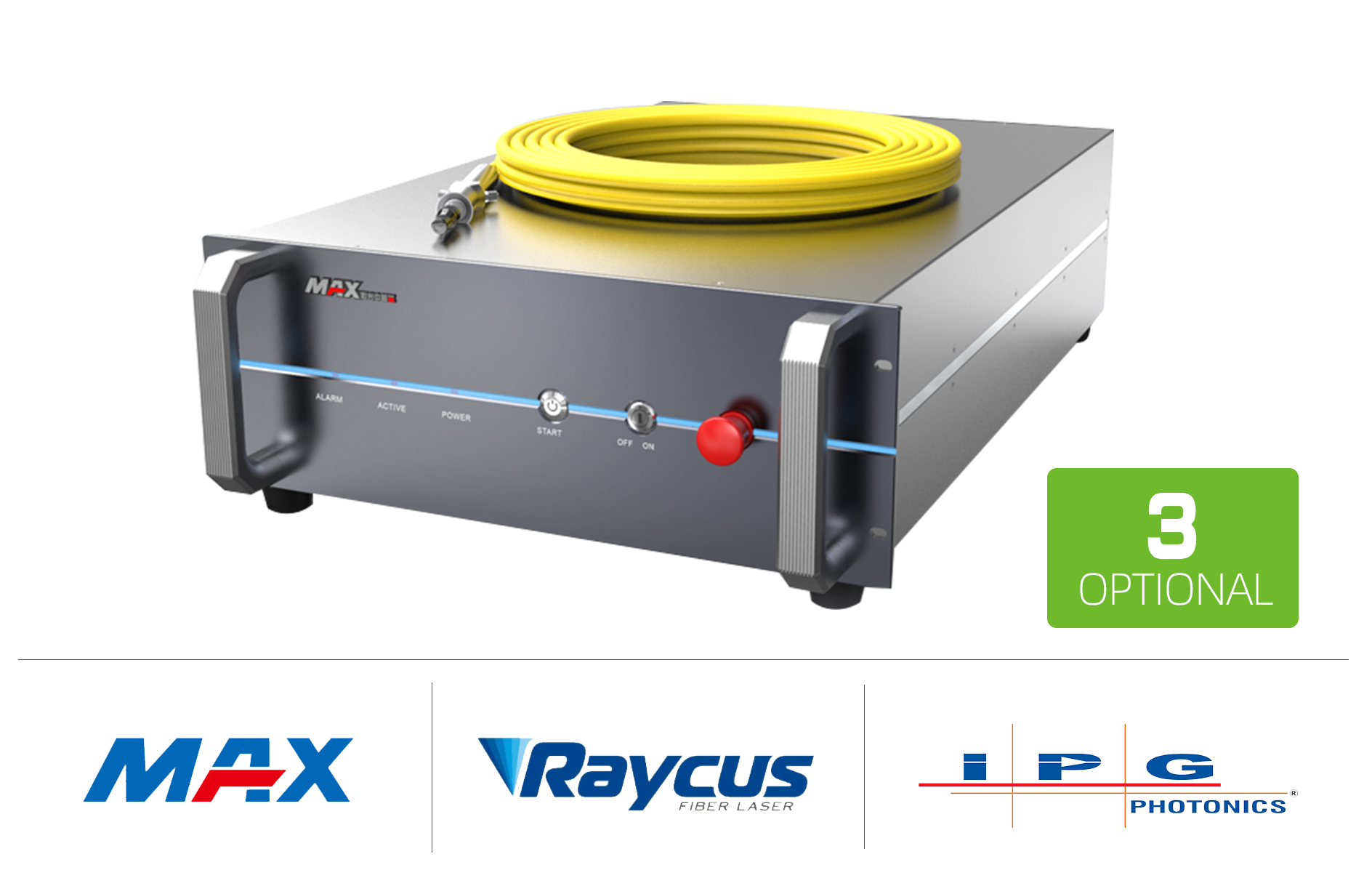

RAYCUS MAX SUNLITE Fiber Laser Source Optional

Compared with similar products,the RAYCUS MAX SUNLITE Fiber laser Source has a higher photoelectric perfor-mance conversion ability ,a more stablebeam,and a stronger anti-reflection ability.

Optional laser power range from 1000 watts to 2000 watts. We have an efficient and professional R&D and production team, which is the top quality in China.The lasers have higher electro-optical conversion efficiency, higher and more stable optical quality.

OSPRI (QILIN) Fiber Laser Welding Head

1. Swing welding head

The process that traditional magnetic head cannot complete, the swing welding head only needs to use 70% of the power, which can save the cost of the laser; In addition, the swing welding method is adopted, the width of the welding joint is adjustable, and the welding fault tolerance is strong, which makes up for the small shortcomings of the laser welding joint. The tolerance range and welding width of the processed parts are enlarged, and a good welding forming effect is obtained.

2. 360 degree micro welding

After the laser beam is focused, the point can be accurately positioned and used for group welding of small and micro workpieces to achieve mass production.

3. Handheld laser welding head Nozzles

When we have a fiber handheld laser welder and replace the welding nozzle with a cutting nozzle, we can call it a handheld fiber laser welding and cutting machine. Isn't it a great name!

It can take the optical fiber from the fiber laser and gather it to a tiny point to produce a high intensity laser for cutting purpose. However, please note that it is not able to cut too thick material.

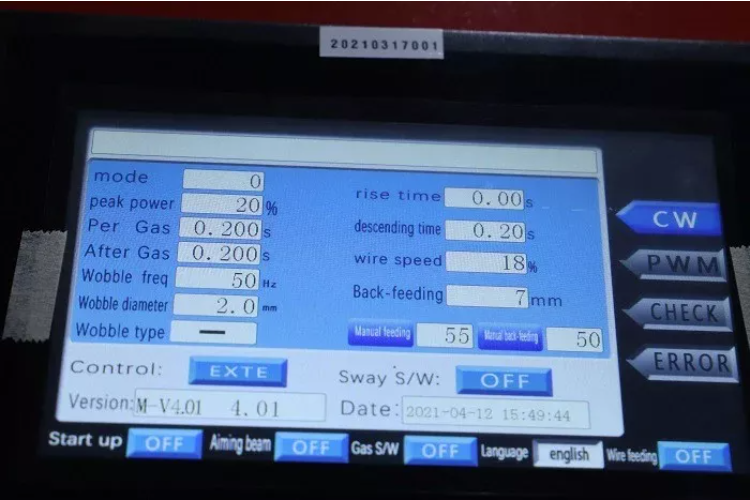

OSPRI Control System

The OSPRI control system is special designed to compect with it's OSPRI laser welding head. It comes with a few kinds of mode,CW model, PWM model Arc model.

The control screen directly digitally sets the parameters of the wire feeder.

The system monitors the operating status in real time, monitors and collects the operating status of the laser, chiller, and control board.

Support Chinese, English, Korean, Japanese, Russian, French, Spanish, Israeli language systems.

HANLI Water Chiller FOR LASER WELDER (OPTIONAL)

Hanli Water Chiller Specially developed for fiber laser equipment, excellent cooling effect. Stable and reliable performance, low failure rate, energy efficient.

Automatic Wire Feeder

The dual-drive wire feeding structure makes the wire feeding smoother and stronger without wire jamming; Closed chassis design, with liftable handle and universal wheel; Wire feeding regulator, LED screen dis-plays real-time wire feeding speed; High-precision speed control knob, and good wire feeding speed controllability.

1000W and 1500W support 0.8mm 1.0mm 1.2mm wire, 2000W support 0.8mm to 1.6mm.

Wire send and back speed adjust through touch panel.

If two weld metal gap more than 0.2mm that need filler wire.

Product Advantage

FIBER LASER WELDING Vs. Conventional TIG Welding

FIBER LASER WELDING

Simple operation, greatly reducing labor costs.Indirect radiation is small. Fast speed and efficiency is 3-8 times that of argon arc welding.Concentrated energy and little influence of thermal deformation.Fine welding seam, deep molten pool, high strength. Very thin materials can be welded, such as 0.05mm stainless steel.Both autogenous welding and additive welding are OK.

Conventional TIG Welding

Professional and technical requirements are high,which leads to high labor costs. Great harm to human body. Slow and inefficient. The thermal influence is great,which leads to large deformation. The welding seam is rough and irregular. It needs grinding and polishing. Not able to weld too thin materials. Consumables welding wire is needed. Easy to weld through.