2000w handheld laser welder

TECHNICAL PARAMETER

Introduction

With the continuous development of the automotive industry, the requirements for vehicle production efficiency and quality are also gradually increasing. In the process of automobile production, body welding is a crucial step, and handheld welding machines play an important role in this process. This article will provide a detailed introduction to the application of handheld welding machines in body welding.

Introduction to Handheld Welding Machine

Handheld welding machines are efficient and flexible welding equipment widely used in various industries such as automotive manufacturing, mechanical maintenance, and construction. It has the advantages of convenient portability, simple operation, and easy maintenance, therefore it plays an irreplaceable role in body welding.

Application of handheld welding machine in vehicle body welding

Improving work efficiency: Using a handheld welding machine for body welding can significantly improve work efficiency. The operation of handheld welding machines is simple, and skilled workers can perform multiple welding operations simultaneously, greatly shortening the production cycle.

Stable quality: The handheld welding machine has stable welding quality and can meet various strict process requirements. By precise current and voltage regulation, the stability and reliability of welding points can be ensured.

Strong flexibility: The handheld welding machine is easy to carry and can be used in different working environments. This allows for flexible adjustment of welding positions and angles according to actual needs during the body welding process, adapting to various complex welding needs.

Cost reduction: Compared to traditional spot welding machines, handheld welding machines have lower acquisition and maintenance costs. Meanwhile, due to its efficient welding performance, it can reduce the workload and time of workers, thereby reducing labor costs.

Conclusion

In summary, handheld welding machines play an important role in body welding. Its efficient, flexible, and stable characteristics give it significant advantages in improving production efficiency, ensuring product quality, and reducing production costs. With the continuous development of technology, the application prospects of handheld welding machines will be even broader.

APPLICATION

widely used in most mainstream industries

Widely used in kitchen utensils, door and window guardrail, stair elevator, stainless steel, hardware board Materials, craft gifts, automobiles, aerospace and other industries

Guardrail

Kitchen, bathroom and utensils

Advertising industry

Stainless steel product

Auto parts industry

Lighting rack

Machine Building

TECHNICAL PARAMETER

| LASER POWER | 1000W | 1500W | 2000W |

| Melting depth (stainless steel, 1m/min) | 2.68mm | 3.59mm | 4.57mm |

| Melting depth (carbon steel, 1m/min) | 2.06mm | 2.77mm | 3.59mm |

| Melting depth (aluminum alloy, 1m/min) | 2mm | 3mm | 4mm |

| Automatic wire feeding | φ0.8-1.2 welding wire | φ0.8-1.6 welding wire | φ0.8-1.2 welding wire |

| Power consumption | ≤3kw | ≤4.5kw | ≤6kw |

| Cooling method | water cooling | water cooling | water cooling |

| Power demand | 220v | 220v or 380v | 380v |

| Argon or nitrogen protection (customer's own) | 20 L/min | 20 L/min | 20 L/min |

| Equipment size | 0.6*1.1*1.1m | 0.6*1.1*1.1m | 0.6*1.1*1.1m |

| Equipment weight | ≈150kg | ≈170kg | ≈185kg |

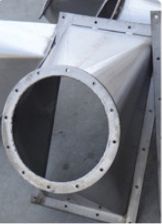

Packing & Shipping

The machine would be packed in solid wooden crate for international shipping, suitable for sea, air and express transportation.